|

| Photo of Miniature Grain Dryer |

|

Designed by Jack Lazor,

Butterworks Farm

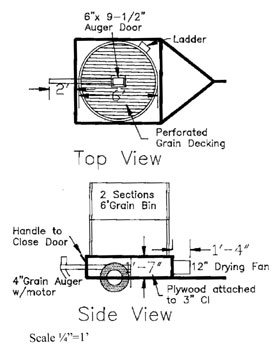

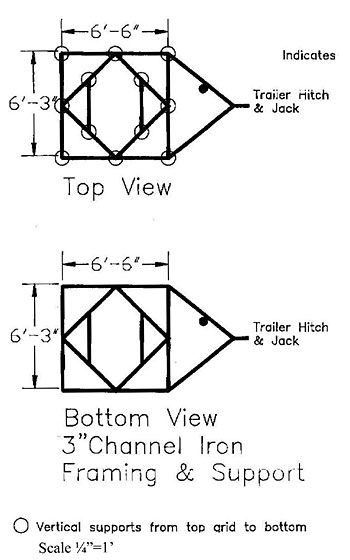

This small scale grain dryer is a scaled down version of a larger flat bottomed aeration grain bin. The vessel consists of corrugated, galvanized rings from a six-foot diameter hopper bottom farm grain bin. Instead of placing these rings on a cement foundation, as would be done with a larger stationary bin, the rings are installed on top of a scaled plywood box built around a frame of three inch channel iron. A hole measuring 5′ 10″ in diameter is cut into the top of this plywood boot or plenum. Perforated grain bin flooring is snapped into place over this hole. It is very important to fashion the three inch channel frame with all the steel shown in the diagram so that the flooring is supported well enough to carry the weight of the grain.

For ease of emptying the dryer, a hopper boot with sliding door is mounted in the floor, attached to a four inch auger which runs under the floor and out the back of the plenum. The drive motor is attached to the top of the auger at the outlet end. Air drying of the grain is accomplished with a twelve inch axial fan which is mounted on the front side of the plywood plenum. Please note that both the unloading auger and the drying fan must be sealed with some kind of caulking, like silicon, so the air goes up though the perforated floor and grain, instead of leaking out of the plenum.

Lastly, install the six foot diameter grain bin rings on the top of the plenum. Use homemade L-brackets to insure the bin walls remain solidly attached. The joint between the steel rings and the plywood top must also be well sealed to insure no loss of air. Two grain bin rings seem to work well, but three may also be considered. A homemade ladder built of standard rebar can be attached to both the inside and outside walls for cleaning and sweeping out the dryer.

Instructions for Grain Dryer

The dryer is portable because an old trailer axle has been mounted underneath the lower frame. A two ring dryer like this can hold over two tons of grain, so block the plywood box or plenum up on all four corners to support the weight of the grain. Make sure the dryer is positioned where it can be easily emptied. Do not try to move the dryer when it is full, because the tires and axle will not support the weight.

To develop proper static pressure the floor must be entirely covered with grain. Bare spots on the floor will channel all the air so the grain will not be evenly aerated. Very small amounts of grain can be dried (2-3 inches) as well as full loads. If you wish to use some kind of low temperature heat source channel the heat to the front of the fan. We have had good success using a two foot diameter cardboard “sonna tube” to conduct heat from a Modine wall heater to the fan. Test grain moisture often and dry to the recommended moistures for long term storage of beans, grain, and oilseeds.

|

|