By Caleb P. Goossen, Ph.D., MOFGA Crop Specialist

As the extent of per- and polyfluoroalkyl substances (PFAS) chemical contamination of agricultural systems began to be better understood in Maine in 2022, MOFGA chose to initiate our own due diligence (as did many other businesses and organizations, I hope). Our initial testing was performed on water from several wells, and also on two composts that had been created from waste materials from the 2019 Common Ground Country Fair (“serviceware 2019” and “food waste 2019”). The good news was that MOFGA’s primary well results, representing the supply for the Fair and MOFGA’s main office building, came back completely non-detect for all PFAS they were analyzed for. Similarly, one compost made from food waste and animal manure came back completely non-detect. Follow-up testing of an older pile of the same type of food waste compost from a prior Fair showed relatively minimal contamination, which I suspect resulted from accidental cross-contamination of another material that contained higher levels of PFAS.

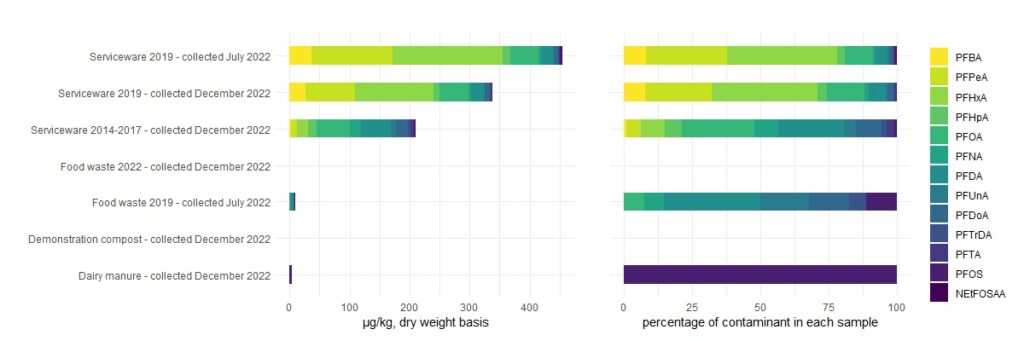

The testing did not return exclusively good news, unfortunately. Another well farther away on MOFGA’s campus tested at a level that was slightly above the state’s interim drinking water standard for the sum of six PFAS compounds (PFOA, PFOS, PFHpA, PFNA, PFHxS and PFDA less than or equal to 20 nanograms/liter) and had to be fitted with an activated carbon filtration system — which was successful. More concerning, however, were the results from the most recent batch of serviceware compost made primarily from local dairy manure and food serviceware (i.e., compostable plates, bowls, napkins, takeout containers, etc.), which food vendors have been required to use at the Fair for many years to reduce single-use disposable waste. The results were, as I said at the time to MOFGA’s buildings and grounds director, Jason Tessier, “impressively high.” They show that composts made with largely uncontaminated dairy manure and serviceware can contain 20 to 45 times the total PFAS concentration compared to compost made primarily with food waste (Fig. 1). Single-use disposable food serviceware materials lack the impermeability of plastics and, for decades, have often been treated with PFAS because of their water- and oil-resistant properties. Our findings showed that this was also true of serviceware materials marketed as “compostable” — at least prior to the 2019 Fair when these materials were used.

Thankfully, it was quickly established that it was unlikely that the food serviceware compost created much of a PFAS exposure risk for anyone, as the focus of the exercise had been on waste reduction, and the finished product had not yet been land applied. Since 2015, food serviceware and food waste generated by the Fair have been sorted and composted separately; prior to then, the supposedly compostable food serviceware had never satisfactorily broken down under MOFGA’s low-tech composting conditions. Because MOFGA staff and Fair volunteers had already been experimenting with new strategies to compost food serviceware separately, we found ourselves with an unplanned opportunity to assess PFAS contamination related to “compostable” food serviceware. We are fortunate to not have any commercial interests in producing compost — which is to say, MOFGA has no incentive to hide or minimize our findings. With these things in mind, we decided to make the most of an unfortunate situation, and to use our position to share with the scientific community, and the world at large, the PFAS contamination risk that we realized from compostable food serviceware.

The Compostable Food Serviceware Experiment

To verify our initial sampling results, we contracted follow-up testing of the same two 2019 Fair compost piles, two additional older Fair compost piles, two compost piles from the 2022 Fair and a sample of manure from the same local source used previously for co-composting with the food serviceware generated by the Fair. Professors Jean McRae and Rachel Schattman, from the University of Maine, were kind enough to assist me in preparing and submitting a write-up of our findings, which was published in the peer-reviewed journal Biointerphases, as part of a special topics collection titled “Per- and Polyfluoroalkyl Substances (PFAS) at the Interface of Biological and Environmental Systems,” in early June of this year. Though it was an additional cost, MOFGA was committed to open-source access for these results, and as such anyone can view and download the entire write-up here: https://doi.org/10.1116/6.0002746.

To the best of our knowledge, we accidentally created a compost with the highest level of PFAS contamination recorded, compared to other published reports on PFAS in composts made without any biosolids (wastewater treatment sludge) as a feedstock. Thankfully, it seems unlikely that this kind of very high PFAS concentration scenario will occur in most real world situations, however it could in similar instances of food serviceware being composted in a segregated waste stream. Lower contamination levels that are likely impacting a greater quantity of composts that include food serviceware as feedstocks are still of concern, particularly when used in cropping systems that rely on large quantities of compost amendments (e.g., some raised bed mixes and some approaches to organic no-till production).

PFAS Concentrations in Compost and Compostable Serviceware

So where did all of these PFAS compounds come from? We cannot say anything definitively about the different food serviceware products that were included in our composting operation, as our investigation was made after the fact and could never be considered a truly controlled, replicated study. However, as we summarize in the introduction to our article, two recent publications examining food serviceware and packaging found highest levels of specific PFAS compounds in molded fiber products (e.g., bowls, plates, takeout containers) that were marketed as compostable or biodegradable. Because the most accurate way to quantify individual PFAS compounds requires prior selection of PFAS compounds to “look for” and measure, there are great limitations to identifying the PFAS compounds present and determining the totals of each. The studies mentioned above determined that their targeted PFAS analysis only identified less than 1% of the total organic fluorine to less than 6% of the total fluorine present in the materials they examined. This suggests that PFAS in use in the molded fiber products are not commonly targeted for analysis and/or are bound up in larger compounds, like side-chain fluorinated polymers.

Though we often think of PFAS as “forever chemicals,” these larger compounds, and other relatively newer PFAS chemistries (called precursor compounds), do appear to undergo some transformations when subjected to the microbial actions of the decomposition process, resulting in smaller PFAS molecules that are more in line with what are more commonly looked for with targeted analysis. This suggests that the concentration of PFAS compounds more routinely looked for (see Fig. 1), and slightly better understood in terms of potential human health risks, might be expected to appear as though they are increasing in concentration in compost over time, as they are the terminal end products of the transformation of other larger PFAS compounds, and will not be broken down further, and because the organic matter fraction that makes up the majority of compost continues to be respired away in normal compost mineralization.

Although we don’t know how manufacturers’ formulations may have changed over time, our findings also suggest to me that as the processes described above continue, longer-chain (larger) PFAS molecules that have been liberated or are the end products of microbial transformations build up over time (e.g., greater concentrations of PFNA, PFDA, PFUnA, PFDoA in compost made several years prior), while small shorter-chain PFAS molecules are possibly leached out of the material into ground or surface waters after they are liberated from the materials and/or larger compounds they were associated with. This would not be particularly unexpected, as shorter-chain PFAS compounds are typically less likely to attach to soil and/or compost particles due to their chemical characteristics.

Looking Ahead

It is worth repeating that our findings are from an unusual circumstance: The composts in question were made from approximately 60% food serviceware by volume. Most composts would not be expected to contain nearly as much of these types of materials, and composts approved for use on certified organic farms do not permit the inclusion of non-approved synthetic substances in feedstocks. The only other PFAS study of compost made including food packaging that we are aware of reported total PFAS concentrations that were nearly six times lower than the highest level we found. They also reported that those levels were approximately 10 times higher than in composts made without the inclusion of food packaging.

While there will hopefully be developments in compostable food serviceware formulations and manufacturing to ensure no further PFAS contamination of composts — and some manufacturers likely have already achieved this aim with some products — it seems that protective regulations may be needed. Maine’s ban on intentionally added PFAS may preclude this concern for materials available for sale in the state after 2030, however, depending upon how the legislation is implemented.

To help address PFAS contamination, MOFGA Fair staff have revised the approved compostable food serviceware list for food vendors at the 2023 Fair. This list now only includes options made by manufacturers that attest they do not intentionally add PFAS, or the items are listed on the Center for Environmental Health’s Database of Single-Use Food Ware Products Tested for Fluorinated Additives.

The waste-management plan for this year’s Fair will separate out food scraps from the food serviceware, and compost them separately, as in previous years. The compost created from the 2023 Fair’s serviceware compost pile will be tested for PFAS to inform our decisions moving forward.

This article was originally published in the fall 2023 issue of The Maine Organic Farmer & Gardener.