|

|

By Heather Omand

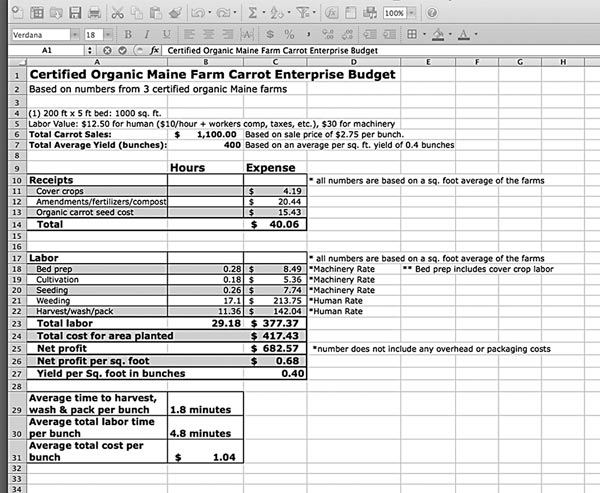

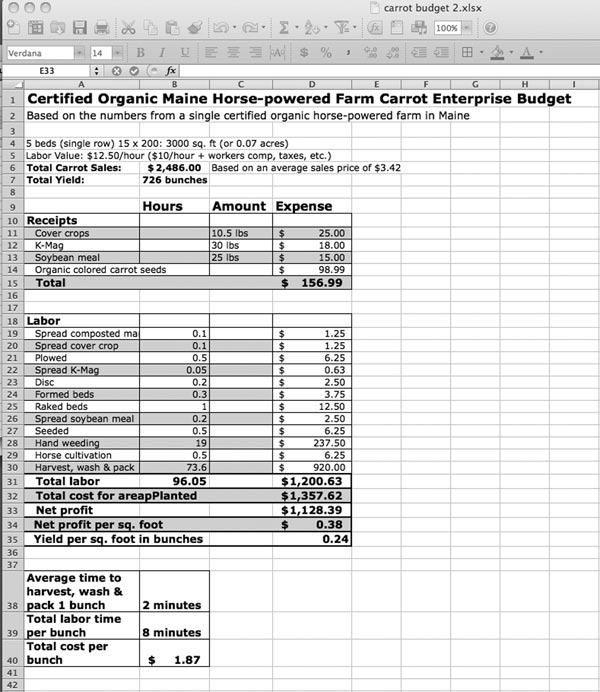

Four MOFGA-certified organic Maine farms – three machinery-powered and one horse-powered – participated in 2015 in a carrot enterprise budget project. Results are presented here, with the horse-powered farm enterprise budget separate due to substantial differences in costs versus the machinery-powered farms.

Some farms tracked certain pieces of information more successfully than others, so numbers in the machine-powered enterprise budget don’t always represent information from all three farms, but they always represent information from at least two.

The farmers in this project began by using a labor tracking system developed by Chris Blanchard of Purple Pitchfork consulting services. Farmers from two of the four farms valued the system, one ended up tracking labor with a smartphone instead, and one preferred and used existing recordkeeping systems. Some believed that they did not capture their labor or yields with 100 percent accuracy but that they captured enough information to generate a useful enterprise budget.

These are basic enterprise budgets intended to give farmers baseline information to evaluate the profit potential of scaling up carrot production, of producing certified organic carrots, or to compare with an individual farm’s enterprise budget. The farmers varied significantly in labor and receipt costs. The budgets demonstrate that farmers’ production choices, their efficiency of labor and labor systems, and their crop management (weediness, etc.) substantially affect an individual farm’s costs and cannot be extrapolated safely based on averaged/aggregated information (such as these budgets) when making major farm decisions. They should not substitute for creating enterprise budgets specific to individual production and business realities.

The “net profit” in these enterprise budgets, configured both for the total square feet represented and per square foot, does not include overhead costs such as utilities required to power the business, land costs, and so on. In his book “The Organic Farmer’s Business Handbook,” Richard Wiswall’s overhead costs are 36 percent of his total crop costs for carrots. Extrapolating from this percentage suggests that overhead costs might be $150.27 in the machine-powered budget and $488.74 in the horse-powered budge – but these are rough estimates.

The budgets also do not include costs of packaging carrots for sale, such as bags, rubber bands or ties, labels or boxes. These are important costs to factor in when considering scaling up to sell to larger retail or wholesale markets. Maine Farm Supply, a buying co-op started for Maine farmers in 2015, could help in estimating or lowering these costs.

Regarding scaling up, note that the price per bunch used in the machine-powered budget was $2.75 and in the horse-powered budget, $3.42, so the net profit per acre would be, for the machine-powered budget, $29,621, and for the horse-powered, $16,553, before overhead and packaging costs. However, few producers will find wholesale buyers willing to pay these prices. Bringing the price down to $2.00 per bunch, net profit per acre drops to $16,553 for the machine-powered budget and $1,307 for the horse-powered budget. Depending on the wholesale market, prices closer to $1.00 per bunch or per pound may be more likely.

To receive an Excel version of this budget to tailor to your own situation, to try Blanchard’s system on your farm to track labor, or for other organic business information, please email me at [email protected].

About the author: Heather Omand is MOFGA’s organic marketing and business coordinator.