Hoskins said that growing crops in the ground in high tunnels is a hybrid of growing them in open fields and in pots on greenhouse benches – with benefits and problems of both.

Because all water has to be supplied in hoophouses, diseases are more easily controlled, and fertigation (fertilizing and irrigating simultaneously) is possible. These soils, then, resemble irrigated deserts more than typical Maine soils.

Problems unique to hoophouses include temperature extremes, which require ventilation; the possibility of more insect problems; and the possibility of nutrient deficiencies due to faster crop growth under warmer conditions.

Also, nutrient salts accumulate, including carryover of available nitrogen (N) as nitrate (NO3), due to faster mineralization (release of nutrients from organic materials), especially under black plastic. The enhanced evaporation in hoophouses “wicks” salts to the surface, but natural rainfall is unavailable to leach these excess salts, and irrigation is usually insufficient to leach them.

Soil Testing Systems

The traditional soil fertility test, used on field soils, extracts a quantity of available, soluble nutrients and evaluates the capacity of the soil to supply these nutrients over the entire season. A defined amount of soil is mixed with a defined amount of water and extraction solution. These tests treat soils as nutrient storehouses, and results correlate well with uptake and yield for the season. Regional tests are specific to the local mineralogy, climate, management practices and nutrient chemistry, and each U.S. region has its own soil test recommendations.

To understand another test – the soil water test – Hoskins explained that plants take up most nutrients as water-soluble, positively charged cations (Ca+2, K+1, Mg+2) or negatively charged anions (NO3-1, H2PO4-1, SO4-2). At any one time, a small proportion of this ion supply is in the soil water solution (the water around soil particles) and is immediately available to plants. As plants absorb these ions and deplete their concentrations in the soil water solution, they are replenished from reserves on cation exchange sites (Ca, K, Mg), from stable compounds or complexes (P, S), and from microbial activity, or mineralization (N, P).

Soil water tests measure concentrations of immediately available nutrients, or “nutrient intensity” – that is, nutrients that are already in solution – but not the long-term capacity of the soil to provide nutrients.

A saturated media extraction (SME) is the most common way to measure nutrient intensity. Soil is placed directly (without drying) in a container, and enough distilled water is added to saturate the soil without having standing water on it. Growers can do this themselves if the have an EC (electrical conductivity) or pH pen. The amount of water in the saturated soil is almost always about double the amount that would be in the soil after it drained for 24 hours to reach field capacity (the maximum amount of water a soil can hold after it has drained). Let the saturated soil equilibrate for about an hour to an hour and a half, then carefully put the pH electrodes in the soil/water paste and measure the pH directly. Measure EC in water filtered from the saturated soil.

The SME test is commonly used when nutrients are applied as water-soluble fertilizers, as in conventional and organic greenhouse bench crop production; and when the nutrient content of the soil significantly exceeds the capacity of that soil to hold nutrients – as in greenhouse production systems that use peat-based potting mixes, which have a finite capacity to bind nutrients. Growers typically exceed that capacity, whether they use synthetic chemical or organic nutrient sources, after growing crops under cover long-term; then their soils have a lot of free salt content.

|

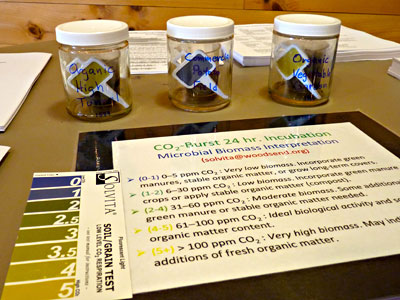

| The Maine Soil Testing Service recently added a $10 Solvita-based soil test that measures CO2 to evaluate soil microbial biomass and activity. English photo. |

Testing Systems for High Tunnels

The first season of high tunnel soil management is essentially the same as open-field soil management, so a routine field soil test enables growers to optimize pH, organic matter and nutrient levels.

After a couple of years, however, salts can build up if houses are not uncovered periodically. Growers should monitor the total soluble salt level to avoid desiccation damage, which can kill plants. Also, tests for open field soil N management do not apply to hoophouse soils after a couple of years, because nitrates build up. Instead, monitor the nitrate level to avoid over-fertilizing. An SME test can be the best option for this.

Hoskins mentioned that one grower whose high tunnel soil had a high salt concentration (8.5 millimhos of soluble salts/cm; the ideal is less than 2.0 mmhos/cm) had the local fire department, when it needed to cycle the water in its truck tanks, empty three tanks of water through the hoophouse soil, adding 4 to 6 inches of water. (The edges of a hoophouse would have to be impermeable to enable the water to move downward through the hoophouse soil rather than laterally, out of the house.) That reduced the salt concentration to 3.08. (Grubinger says 3 to 4 is typical for greenhouse soils prepped for tomatoes.) Alternatives include rolling the plastic to the peak of the house for at least a month or for three or four good rainfalls; flooding the soil with well water; or using overhead irrigation for a few weeks until it runs through the soil (but the soil does not run off). Do this, ideally, before planting a new crop. This leaches excess nutrients, but not reserve nutrients. Ideally, dry soil samples have 20 to 30 parts per million (ppm) NO3; the soil testing lab is seeing soils with 200 to 300 ppm.

Maine’s high tunnel package is a hybrid soil test designed to cover a variety of hoophouse situations – new, old, always covered, sometimes uncovered, moved, not moved. The field soil test portion addresses the total capacity of the soil to supply nutrients; an SME test monitors total nutrient and salt buildup; and an available N test addresses NO3 buildup. The lab recently added a $10 biological test, as well: a Solvita-based system that measures CO2 to evaluate soil microbial biomass and activity.

Vermont’s System

Vern Grubinger said that tomatoes are the dominant hoophouse crop in Vermont, but more greens are being added – producing a diversity of crops and conditions. Without soil testing, growers could be losing a significant amount of their potential yield without knowing it. In a 30- by 100-foot tunnel with tomatoes with a crop value of about $20,000, even a 5 or 10 percent reduction is a lot of money lost. So, it makes sense to avoid nutrient-related losses by spending $15 on an SME test, and then $25 for tissue analysis, said Grubinger. “The data from the lab will be precise, even if we are guessing a bit with the recommendations; the goal is to help guide your fertilization practices.” He suggested picking one lab and sticking with it in order to compare results over time.

Grubinger converted test results for conventional crops (in “Greenhouse Tomatoes, Lettuce and Cucumbers,” by S. H. Wittwer and S. Honma, 1979, Michigan State Univ. Press) to guide growers using hoophouses and organic soil fertility practices (Tables 1 and 2). Plants can still grow well if the soils are a little out of the optimal ranges in Table 2, but the further from optimal you go, the more likely yields will be reduced.

Since the Farmer to Farmer workshop, Grubinger has worked with Hoskins to modify the optimal ranges found in the literature to better reflect the realities growers are seeing in their tomato greenhouses. These ranges, which continue to be refined, are listed in Table 1.

Table 1. Optimal soil nutrient levels for greenhouse tomatoes using the SME test

| pH | 6.5 – 7.0 |

| NO3-N | 125 to 200 ppm |

| NH4-N | <10 ppm |

| P | 3 to 10 ppm |

| K | 175 to 275 ppm |

| Ca | >250 ppm |

| Mg | >60 ppm |

| soluble salts | 2.0- 4.0 mmhos |

To do the SME test, take a representative sample of hoophouse soils (10 or 12 subsamples from across the house) before adding any soil amendments, said Grubinger. Keep the soil warm and moist for a week or two, either in the greenhouse first, or by bringing it into the home. Then send at least a pint of it to the soil test lab in clearly labeled a Ziploc bag.

Grubinger presented contrasting sample results from two UMass SME soilless greenhouse media tests. (Table 2)

Table 2. SME test results for two soilless greenhouse media samples

| pH | 6.2 | 7.4 |

| soluble salts (mS/cm) | 4.97 | 1.25 |

| NO3-N | 520 | 72 |

| NH4-N | 1 | 0 |

| Phosphorus | 66 | 3 |

| Potassium | 539 | 23 |

| Calcium | 376 | 139 |

| Magnesium | 280 | 43 |

Nitrate N is more than twice the optimum in the first soil, so this is a very fertile soil.

Ammonium should be close to zero, because microbes should be actively converting N compounds to nitrate. If NH4 is high, the medium has “microbial constipation”: Decomposition got stuck, and that will be a problem until the population in the medium re-equilibrates, said Grubinger. Organic acids may be suppressing microbes, for example, but once the acids are broken down, the microbes can resume their jobs. Planting into a high NH4-N soil, however, can damage plants directly.

Grubinger said he worries less and less about P concentrations on the low side, because greenhouses and their soils tend to have a lot of P in reserve that the SME test does not measure, especially if there has been much compost added. “I just don’t see P deficiencies in these houses.” Also, the SME test doesn’t measure reserve P. “So unless this is below 3 ppm, I’m not going to recommend any more P.”

Potassium is low in the second sample. Since greenhouse tomatoes remove a lot of K, a deficiency will limit production. Low Ca in the second sample could induce blossom end rot.

Low nutrient levels are associated with low salt readings. “You want an optimal range of salts,” said Grubinger. “Lower is not always better.”

In 2008 and 2009, Grubinger sampled 75 soils growing greenhouse or tunnel tomatoes. He concluded that most growers need to do the SME test, because most results were out of the optimal ranges. Most had optimal pH levels, but few were optimal for NO3-N. Many were so low that, although they may or may not release more N later, they would starve the crop in the short term. Many soils had a great excess of NO3-N. This won’t leach from a covered tunnel, said Grubinger, but can reduce crop quality, producing excess vegetative growth.

About five samples had very high NH4-N – possibly from fresh poultry manure or blood meal.

Ten or so with very high P rates should not add any more compost or fertilizers that are blends of nutrients. When the plastic comes off these houses, these soils could pollute through runoff.

Several soils were very low in K, and some were astronomically high.

Salts ranged from very low to very high. “I was surprised… that these plants [in the high range] were not dead,” said Grubinger, but tomatoes are somewhat salt tolerant. Greens may not be so tolerant, and herbs and flowers will not grow well. Dry soils exacerbate the salt problem.

To limit the addition of excess P and K once these are high, use materials that supply only the nutrients that are needed; that means using amendments other than manure or compost to supply nitrogen, said Grubinger. The following elements are supplied by the materials noted:

| Ca | lime gypsum (mined) |

| Mg | dolomite (also Ca) sul-po-mag (also K) Epsom salts |

| P | rock phosphate (0-3-0) bone meal (0-15-0) bone char, which is more available (0-16-0) |

| K | potassium sulfate (0-0-52) sul-po-mag (0-0-22, 11 Mg) |

| N | dried blood (12-0-0, but this can produce excess NH4+ quickly) Chilean nitrate (16-0-0). Chilean nitrate can supply only up to 20 percent of the N need in organic operations – or about 9 pounds per 1,000 square feet for greenhouse tomato crops. alfalfa meal (2-1-2) soybean meal (7-2-1) peanut meal (8-1-1) |

| Blends | pelletized poultry manure and other blends – but only if soils need P as well |

| Micronutrients | borax, chelates, sulfates |

Keep things in balance, said Grubinger. “When all the nutrients are high, things seem to work OK, but when one is low while another is high, you can have induced deficiency, because Ca, Mg and K all compete to get into the plant.” He gave the following recommendations for greenhouse soils, with amendments incorporated completely into the top 12+ inches of soil:

Table 3. Estimated fertilizer rates (lbs./1,000 sq. ft.) to increase SME nutrient levels

To raise N approximately 10 ppm

Chilean nitrate – 3.2

Blood meal – 4.2

Alfalfa meal – 20.1

Soy meal – 7.2

To raise P approximately 2 ppm

Bone meal – 26.6

Rock phosphate – 133

To raise K approximately 20 ppm

Sul-po-mag – 2.6

Potassium sulfate – 1.1

Table 4. Estimated fertilizer rates (lbs./1,000 sq. ft.) to alter Ca in greenhouse soils

To raise Ca approximately 25 ppm

Calcium sulfate (gypsum) – 7.5

Calcitic lime – 7.5

Dolomite (high mag lime) – 5.3

Pounds of lime/1,000 sq. ft. to raise the pH approximately 1 unit. Use calcitic or, if magnesium is needed, dolomitic (high magnesium) lime.

sandy soil – 40

loamy soil – 80

clayey/high organic matter – 120

If soils are too high in nutrients, growers can add peat moss, which also dilutes salts and changes the water holding characteristics of the soil. Grubinger recommended about 1 yard per 1,000 square feet, mixed in thoroughly. If the soil pH is good, add 8.5 pounds of lime per loose cubic yard of peat moss, or 17 pounds of lime per compressed yard, to keep the soil pH neutral – unless you’re using that peat moss to lower the pH. Peat moss has a pH of about 4, and a compressed yard equals about 2 loose yards.

Grubinger said vast reserves of peat moss exist. “In a perfect world we would not need to use this. But it’s not a perfect world. You need organic matter but not nutrients… you could make some quality leaf mold that’s pretty low in nutrients. We’re not talking a whole lot. I don’t recommend peat moss for use on a field basis.”

Grubinger presented his recommendations for three greenhouse soils based on SME results:

Soil 1 – A compost-amended soil with about 60 to 70 percent field soil had the following analysis, based on the SME test:

pH – 6.8

Soluble salts – 1.27 mS/cm

Nutrients (mg/L or ppm)

Nitrate-N – 35

Ammonium-N – 0

Phosphorus – 0

Potassium – 13

Calcium – 182

Magnesium – 40

Recommendations for 1,000 square feet, growing tomatoes:

1/2 cubic yard of compost to build up N, P, K plus organic matter.

25 pounds blood meal for nitrogen

100 pounds soybean meal for nitrogen

20 pounds sul-po-mag for potassium and magnesium

25 pounds gypsum to raise calcium without raising the pH

Soil 2 – A medium containing about 15 percent field soil

pH – 7.2

Soluble salts – 4.65 mS/cm

Nutrients (mg/L or ppm)

Nitrate-N – 456

Ammonium-N – 1

Phosphorus – 8

Potassium – 334

Calcium – 200

Magnesium – 143

Recommendations for a tomato crop:

1 cubic yard loose peat moss to add organic matter and dilute some of the nitrate-N

4 pounds lime to neutralize the peat moss additions

25 pounds gypsum to add calcium without raising the pH

Soil 3 – A medium with no stated percent of field soil

pH – 7.2

Soluble salts – 1.40 mS/cm

Nutrients (mg/L or ppm)

Nitrate-N – 110

Ammonium-N – 0

Phosphorus – 4

Potassium – 34

Calcium – 126

Magnesium – 65

Recommendations for a tomato crop:

1/2 cubic yard compost for N, P and K

50 pounds soybean or peanut meal for nitrogen

8 pounds potassium sulfate for potassium

10 pounds gypsum to add calcium without raising the pH

Managing N and K in greenhouse tomatoes is usually the big issue, said Grubinger.

Once the plant is growing, he recommends spending $25 for a leaf analysis several times during the growing season. Take 10 or 12 whole leaves when the fruit is about golf ball-size. Use recently matured, fully expanded leaves from just below the last open flower cluster. Strive for concentrations in Table 5.

Table 5. Optimal leaf tissue nutrient levels (dry weight) for greenhouse tomatoes by latest open flowers

| N | 2.5 to 3.5 percent |

| P | 0.5 to 1.0 percent |

| K | 6.0 to 10 percent |

| Ca | 1.3 to 3.0 percent |

| Mg | 0.3 to 1.0 percent |

| Mn | 20 to 100 ppm |

| B | 20 to 40 ppm |

| Cu | 5 to 25 ppm |

Values for other times of crop growth are given in “Organic Greenhouse Tomato Nutrition.” (See resources.)

Asked about adding soil microorganisms, such as mycorrhizae, Grubinger said that greenhouse soils are so high in nutrients that he would be surprised if mycorrhizae are active. He does suggest inoculating for disease control. “Put in a pupu platter of the good guys. Trichoderma, Bacillus…”

He dislikes foliar feeding, since wet leaves foster diseases. Roots are designed to take up nutrients, he said; leaves, for photosynthesis. While foliar sprays of seaweed products, for example, may have hormonal effects, he sees preventing leaf mold and botrytis as much more important.

Happy Town Hoophouses

|

| Tomatoes and peppers growing in a hoophouse at Happy Town Farm in Orland, Maine. English photos. |

|

Paul and Karen Volckhausen have about 4 acres of vegetables, many animals and three hoophouses. They bent pipe for their first, 11- by 88-foot hoophouse in the early ’80s, based on a design from Johnny’s Selected Seeds. The house comes apart in sections, and four people can pick up and move each section. It covered tomatoes as they were rotated around the acreage, with Paul adding a little extra compost for the crop and seeing an “amazing” increase in yield and quality. That house now rotates greens, cucumbers, peppers and eggplant.

In the mid-’90s they bought the second house, which does not move – and realized the ground needed a lot more nutrients than the open field, because of the increased tomato yield.

Based on university recommendations, they applied compost to supply N, then other minerals such as rock phosphate and sul-po-mag as needed. When they started hearing about salt buildup in hoophouses, Paul started rolling the sides up to the peaks about every third winter. Previously they kept the house covered and grew a cover crop of winter rye in it.

A test of the hoophouse soil last summer showed many nutrients above optimum but not too far from what Paul wants. He has fairly successfully minimized the salt level in the house that has had tomatoes in it for most of 10 years.

The Volckhausens bought a third house in 2010 and now grow their tomatoes in it. The basis of Paul’s management is to try to incorporate organic matter in the soil using compost and green manures. “I don’t get rye on there every year,” said Paul. When he does, he doesn’t irrigate it all winter. “I’m recycling a lot of nutrients that are building up in the house through that rye.” Because his equipment won’t fit in that house, he cuts the rye down in 6-inch layers with a weed whacker, mixing it in with an old Troy-Bilt rototiller at least two weeks before planting vegetable crops so that it has time to break down; and he spreads a layer of compost. No insect problems have resulted from growing rye in the house over winter.

The Volckhausens’ original small house was in cut flowers, zucchini and salad mix last year.

Q & A

Q. What crops are people growing or thinking of growing in high tunnels?

A. Eric Sideman said the top ones are tomatoes, winter greens and raspberries. Dave Colson added basil. Paul Volckhausen noted that Karen’s zinnias had nice long stems in hoophouses and lasted until the end of October. Other good flowers mentioned were celosia, larkspur and lisianthus; the latter grows much better in tunnels than in the field. Another grower raises early potatoes and overwinters ‘Olympic’ onions, pulling them at the end of May or early June. Johnny’s sells onions specifically for overwintering. Grower Rob Johanson cautioned that onion thrips will overwinter in that environment, so harvest and sell the crop immediately and don’t try to grow another Allium crop in or near the hoophouse. He lost some of his crop to thrips, but treated with Entrust to save the rest. Grower Jim Gerritsen has had success with spring-planted strawberries in a hoophouse.

Q. How viable is it to grow kale or Swiss chard from November to May?

A. Grower Dave Colson found that if these crops aren’t started early enough, they won’t grow big enough, and they can interfere with spring tomato planting. Another grower transplants kale and chard from the field into the hoophouse in early November. They bounce back in late winter. Volckhausen noted that any low cover will protect kale. “You don’t need the expense of a hoophouse.” Paul Arnold seeds chard and kale in August to transplant to the hoophouse in October. Kale, chard and lettuces “won’t be star performers through winter,” he said. “Asian greens and bok choy planted around them are the star performers then, in that low light area. But come March, April, May, [kale, chard and lettuces] produce so much. The star performer in the whole house is Swiss chard,” with an estimated value of more than $300,000/acre (extrapolated from the square footage of the hoophouse), which does better than salad greens then. “It is worth it, but you have to start them in August,” said Arnold.

Q. Can I use lobster waste and chicken manure as nutrient sources?

A. Hoskins said that any kind of seafood waste is good source of N and P. Lobster, crab and mussel shells contain calcium carbonate, so they will increase soil pH and calcium. Cow manure is usually a better source of K and N. Poultry manure is very high zinc and P; contains some lime, which will raise soil pH; and its N is very fast release – so be careful its decomposition doesn’t stop at the ammonia stage. Don’t use these two potent sources of P for long, said Hoskins; and watch the salt level; and the soil may need supplemental K. “You may want to get your own EC [electrical conductivity] pen, make a saturated paste with the soil, filter it off through a coffee filter, and test the conductivity,” said Hoskins. [Ed. note: Near the coast, seagulls may be attracted to compost made from seafood waste and may pierce the plastic of the hoophouse to get at it.] To be sure compost is mature, Johanson suggested Woods End Lab’s easy-to-use Solvita compost maturity test (www.woodsend.org).

Q. Is anyone overwintering animals in hoophouses?

A. One grower overwinters poultry in one house and leaves that fallow the next summer while his second hoophouse produces crops. Then he switches houses. Another overwintered 30 laying hens in a 30- by 100-foot house. Move the roosts weekly, said one grower, to spread the manure evenly. Growers need to remember the 90- or 120-day waiting period before harvesting the crop after animals were in the house. Hoskins suggested that tomatoes following poultry might be a good rotation.

Q. What is the difference between nitrate and ammonium N?

A. Sideman referred growers to his publication “Providing Nitrogen to Crops” at www.mofga.org/Publications/FactSheets/tabid/133/Default.aspx. [See also his column in the March-May MOF&G.] He explained that microorganisms that decompose proteins in living material first release ammonium N; then other bacteria use that NH4+ and release nitrate-N, which plants take up. In open fields, NO3-N can leach, but in a covered hoophouse, it doesn’t, so it can build up. Hoskins said that NH4+ is usually converted to NO3 quickly in hoophouses, and that a high NH4+ level means that the pH is too low, or the soil is saturated and anaerobic – a problem when compost-based potting soils first came out and had too much compost in them.

Q. What is a caterpillar?

A. A caterpillar is a simple imitation of a more solid hoophouse, said Sideman. For his, he put a piece of rebar in the ground every 4 feet, leaving about a foot sticking up. Then he bent 20-foot pieces of PVC piping from one piece of rebar to another. Caterpillars can be as long as growers want by adding more rebar every 4 feet. Plastic is spread over the piping. Another piece of rebar is placed between each hoop along each side of the house, and rope is tied to these rebar pieces and stretched over the house, pulling the plastic taught between each hoop, so the structure looks like a caterpillar. These houses are cheap and are good for crops that don’t need an elaborate structure, but they won’t withstand heavy snow.

Another grower suggested using pipe clamps at the bottom of each hoop, eliminating the need for extra pieces of rebar. “Just pass the cord over from one [clamp] to the other. It holds [the plastic] really tight on the structure.”

Hoskins suggested making clamps from black plastic pipe to hold plastic to the end hoops. “If you have 1-inch PVC, get 1-1/4-inch black plastic pipe, cut a section off, split it down the middle and spread it, and it fits over the PVC.” The pipe spreads easier on a warm day.

Q. What types of houses do growers like?

A. Grubinger said that many strawberry growers use Haygrove houses. “If you’re going to be rolling up plastic every year, I wouldn’t spend my money on a high tunnel,” said Grubinger. “Go to a Haygrove or something with less steel, or a caterpillar. But if you need to cover an area to get into it in February and March, your crop and your market drive the decision.”

Growers like Ed Person’s houses (www.ledgewoodfarm.com, in New Hampshire) and Rimol’s, said Grubinger. “A lot of people start with a 17 or 21 by 50 or 100. Then you have a lot of options, whether it’s tomatoes or not. With a Haygrove, you’re cropping in a much bigger area, and you have to consider high winds.”

Grower Lisa Turner said that the Quonset shape is awkward to work in, as growers brush against the sides and get wet. She likes Ledgewood Farm’s Gothic arch-shaped houses. “They’re cheap and they last.”

Snow load is another issue with rounded houses, said Turner. “It’s not as much an issue if you’re heating them in the winter to melt the snow off.” But in years with 6 or 8 feet of snow sliding off and building up, the weight of the snow can be too much for the house. Sideman suggested leaving enough space between houses to remove snow with a tractor. Gerritsen suggested strengthening these houses with vertical 2 x 4s on stands in the center of the house.

Colson has four 17- by 96-foot houses, some Quonset shaped, “and I wish I didn’t have any of those.” He also has a 30- by 96-foot house, which he doesn’t roll up because of its size, but he can move his field irrigation system into it. “The smaller width greenhouses are the ones it seems to make sense to roll up,” he said, which he does when salts start to build up. He pulls the hip boards and rolls the sides to the peak of the greenhouse, ties the plastic there and covers it with black plastic. He figures he gets another half season out of his four-year plastic by shading it from the sun.

One year Colson rolled the sides up unevenly and the pipes, plastic and everything slid off. Ed Person suggested a remedy, which worked. A center purlin runs the length of the house under the bows. Between every four bows, about five places up and down the greenhouse, Colson attached a 2 x 4 above the purlin with metal strapping. He then put the plastic on, running it over the top of the 2 x 4. Before fastening the plastic on the sides, he screwed a 1 x 4 as long as the space between the bows onto the top of the plastic, sandwiching the plastic between the 1 x 4 and the 2 x 4. He did that about five times – at either end and about three spots in the middle of the house. “Now that cover can’t go anywhere, so when you pull the hip boards to roll it up, everything stays in place.”

Johanson grew kale under 1/2-inch EMT (electrical metallic tubing, or conduit) hoops last fall, covering it with Remay first, then with greenhouse plastic when snow threatened. (See “Extend the Growing Season with Coleman’s Double-Covered Low Tunnels” in the Winter 2007-2008 MOF&G, at www.mofga.org/Default.aspx?tabid=844.) The kale survived the winter fine. He set the hoops about 8 inches into the ground. “Once the ground froze they were strong enough that they didn’t move. We doubled up the bows on the very end where we pulled the plastic over.” In midwinter, his wife, Jan, and other help “did guerilla kale picking” under the tunnel, pushing a basket in front of them, picking the kale, then backing out and pulling the basket out with an attached rope. “We had kale and Swiss chard all winter.”

During the discussion (and in an e-mail later), grower Chris Cavendish described the “quick-houses” he makes, which are large enough to walk in and cost about 70 cents per square foot.

“Each quick-house is 12 feet wide by any length you want,” said Cavendish. “The ground posts are pounded into the ground 12 feet apart and at 4-foot intervals. They are made from 1-5/8-inch steel tubing available in the fencing section of any well-stocked hardware store. They come in 8-foot lengths, which I cut in thirds, giving three pieces, each 2 feet 8 inches long. Then I drill a hole 6 to 8 inches from the top and insert a 5/16-inch eye-bolt and secure it with a nut. To the eye of the bolt I clip a 5/16 carabiner or spring-type link for chains. This carabiner will accept the rope that holds the plastic in place.”

Cavendish makes hoops for the house from 1-inch by 10-foot PVC pipe (two lengths per hoop), prefabricating each hoop on a flat level surface. Previously he has made a 135-degree bend where the two 10-foot lengths join, at the peak of the house, with a 135-degree PVC connector – but he plans to change this design, as this is where the hoops seem most likely to fail. “I have located a hydraulic pipe bender from Northern Tool Supply that is cheap ($150) and seemingly easy to use. I would fabricate connectors at the peak from the same 1-5/8-inch tubing that I used for the ground posts.” Once the 20-foot-long hoops are made, Cavendish inserts them into the ground posts.

Q. How should ground be prepared for hoophouses?

A. The biggest problem Grubinger sees is that houses are not sited well in relation to water flow. “The ground’s frozen, water gets into them, now it’s wet and cold. You really have to look at where the water’s going to go. Water flowing under that house in the winter is going to take the heat away. You really want to be high and dry in these houses.”

Q. What are the most profitable crops per square foot to grow in a hoophouse?

A. Grubinger directed growers to Cornell University’s “Sample budgets and spreadsheets” for high tunnel crops, at www.hort.cornell.edu/hightunnel/business/budget.htm. Other sites are listed at www.uvm.edu/vtvegandberry/budgetlinks.html.

Q. How can you supply fertility during the growing season?

A. Colson learned from a Quebec grower how to supply K to tomatoes midseason: Put 5 pounds of wood ash in a 50-gallon drum, steep it for two or three days, then apply it to the roots – not the foliage – with a watering can. He’s done that on and off for a few years, with good results.

Grubinger said that many organic materials – Chilean nitrate, sul-po-mag, potassium sulfate – can be put in warm water and stirred vigorously to make dilute solutions.

Texas A&M has a ppm calculator at https://aggie-horticulture.tamu.edu/greenhouse/nursery/guides/ghhdbk/ppm.html to help figure out rates. Alternatively, some people shovel compost or a little blood meal on their beds and then drip irrigate over it. He cautioned to spoon-feed with dilute nutrients frequently rather than applying a lot at once.

Q. What does K deficiency look like on tomatoes?

A. Sideman said the edges of leaves are lighter green and the fruit ripens unevenly. Nitrogen and Mg deficiencies are also common in greenhouse tomatoes. Volckhausen sees Mg deficiency fairly regularly. When he does notice symptoms, he dissolves 1 to 2 tablespoons of Epsom salts per tomato plant in enough warm water to dissolve the salts, pours that into a 55-gallon drum on his truck, fills the drum with water, and gravity feeds that solution through drip lines. He does this only once per summer. Magnesium deficiency turns older leaves yellow between the veins, while the veins stay green. Sideman reminded growers that to foliar feed calcium to plants, organic growers have to have a diagnosed calcium deficiency. [Calcium chloride is a natural substance, but foliar feeding with it except during a diagnosed deficiency is prohibited by the National Organic Standards because growers should be building their soil rather than depending on such emergency measures.] Growers don’t need a diagnosed deficiency to feed with Mg or potassium.

Resources

Building and equipment design plans: www.uvm.edu/vtvegandberry/supplylinks.html

Grubinger, Vern, “Organic Greenhouse Tomato Nutrition,” Jan. 2010, www.uvm.edu/vtvegandberry

North Carolina Department of Agriculture, “Tissue Sampling & Analysis for Greenhouse Tomatoes,” 2009, www.ncagr.gov/agronomi/pdffiles/gtomato.pdf

Oregon State University, Greenhouse Tomato production guide, https://nwrec.hort.oregonstate.edu/tomatogh.html

Organic supplies: North Country Organics, www.norganics.com

Papadopoulos, A. X., 1991, Growing Greenhouse Tomatoes in Soil and Soilless Media. Harrow Research Station, Ontario, Canada. PDF available free at www.hydro-gardens.com/books.htm

Paris Farmer’s Union, www.parisfarmersunion.net, delivers to farms. Contact Milton Sinclair or Dick Deans at 1-800-639-3603.

Wittwer, S.H., and S. Honma, Greenhouse Tomatoes, Lettuce and Cucumbers, Michigan State Univ. Press, 1979. Available used from Amazon.

– JE