|

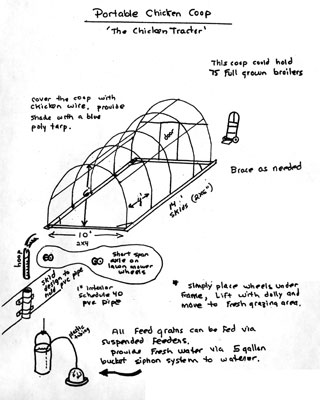

| Cumberland County Extension Educator Dick Brzozowski provided these plans for a portable chicken coop, or “chicken tractor,” at MOFGA’s Small Farm Field Day last August. |

By Richard J. Brzozowski

Raising broiler chicks on pasture can be profitable, and can require few inputs. The system involves purchasing day-old broiler chicks (meat type birds) in late May or June, keeping them in a brooder for three weeks, where they receive ample heat, fresh air, feed and water; then transferring the birds to portable hoop houses, where they have access to pasture and are given some grain and fresh water daily. To find waterers and feeders, check Uncle Henry’s or your recycling center before paying full price for new ones. Wash used feeders with soap and water, then sterilize them with a mixture of 95% water and 5% bleach before using them.

A few tricks can help ensure that most of your chicks survive. Put an extra chain on the heat lamp in the brooder as insurance against burning down a building. Put marbles in the bottom of a small waterer to attract the chicks and enable them to know where the waterer is. Use shavings instead of sawdust in the brooder, because the former are more absorbent. Don’t use cedar shavings, since they are too expensive and may not be good for chicks. Do not clean out the old shavings; instead, add clean shavings on top of the old ones each week so that the old shavings and droppings are not stirred up and spreading pathogens among the chicks.

The hoop house provides protection from extremes of sun and wind. It is moved each day to provide fresh grass and clover to the birds. You can move it more frequently if you have poor or wet pasture. Not only do the birds get fresh pasture when they are moved, but movement limits their exposure to their feces, so problems with pathogens are minimized.

This hoop house system is a little different from the “chicken tractor” used by famous poultry pasturer Joel Salatin. Salatin uses a 10′ x 12′ rectangular box that is 2′ high. Half of it is covered with light weight metal roofing and the other half is covered with chicken wire. With this design, you cannot see the chickens all of the time, and you cannot get in with them. Any barrier to observing the birds will slow you down. Also, Salatin’s chicken tractor cannot be used for anything else, whereas the hoop house can be used for protecting crops as well as chicks (but not at the same time).

|

| MOFGA’s Rick Kipp built this chicken tractor for MOFGA’s Unity site. English photo. |

|

| Wheels can be placed under the end of the “tractor” when it is to be moved. English photo. |

|

| As Kipp moves the potable coop with a dolly, the feeder at the front of the coop moves too – and, if poultry were in the coop, they would tend to follow the feed. This keeps them close to the front of the coop, so that they don’t get crushed by the back end of the coop as it moves. English photo. |

Note that the birds will not graze a lot until the last two or three weeks of their lives. They prefer clover and weeds to grass, and if the grass is too high, they won’t eat it. Mow the area where the house will be moved if the grass exceeds 3 inches in height.

The birds are raised for about eight weeks, when carcasses will weigh about six pounds. (Fryers are raised for about five or six weeks.) Grain is removed 24 hours before slaughter, then the birds can be slaughtered on the farm or at a custom processing site nearby. You can request a free fact sheet on on-farm poultry slaughtering by calling the University of Maine Cooperative Extension in Cumberland County at 1- 800-287-1471 or emailing [email protected].

Advantages

Pasturing poultry is a short-term project: six weeks for fryers; eight weeks for broilers; and 10 to 12 weeks for roasters. It is an inexpensive way to raise meat birds. The $100 investment for the structure is one of the major expenses, and the structure will last through many cycles of birds. Be sure to buy galvanized chicken wire; it will last longer than the non-galvanized.

Pasturing provides a clean, reduced-stress environment with plenty of fresh air and room to move. The birds are easy to observe daily and the grower need spend only about 15 minutes per day per house. At the end of the cycle, one day will be needed for processing, or one-half day if they are being processed at a custom processor.

Not only will poultry thrive under this system, but so will pastures. The birds fertilize your fields as they are moved.

Beak trimming is not necessary when birds have sufficient space and feed. Beak trimming is typically used on chickens that will be kept to full maturity (such as laying hens).

Possible Problems

Some chicks may be lost during the brooding period due to genetic factors or disease. Modern breeds have been bred for a commercial industry that demands fast growth; consequently, some are prone to heart attacks or weak legs. As soon as you see a droopy chick, rogue it out.

Birds may be lost to predators that dig under the house. To minimize this problem, run a single-strand electric fence around the house on six size C flashlight batteries. The fence should be 4 to 8 inches from the ground.

When the house is being moved, chicks can be injured if they get “run over” by the back sill of the house. To help prevent this, put a tarp over the front of the house; and fill the feeder before you move the house. As the feeder moves, so will the birds. Also, watch the birds carefully as the house moves. The chickens learn fairly quickly that when the house moves, they move.

Limitations

The 140-square-foot hoop house in this design can hold about 70 birds (two square feet per bird). It could also be used to house about 20 laying hens, if roosts were added. However, layers and meat birds will not do well together, because they eat different rations. Level land is needed so that the house sits firmly on the ground and can be moved easily. Even with a hand cart (dolly), you’ll need physical strength to lift and pull the house.

Summer is the best time to raise broilers with this method in our climate. When storms threaten, you may have to cover the whole house with a tarp.

About the author: Richard is an Extension Educator with the University of Maine Cooperative Extension, Cumberland Co. Extension Office, PO Box 9300, Portland ME 04104-9300; 1-800-287-1471; [email protected]. He gives presentations at many MOFGA events. Richard raises 60 broilers each year for consumption by his own family and neighbors.

Economics of Pastured Broilers

By the time the first batch of chickens is sold, all of the input costs will be covered. The following items are needed to raise one batch of 65 birds.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|