By Sonja Heyck-Merlin

“Each time we’ve dug a shallow well, the excavator operator looks at me and says, ‘I don’t know Joe, I don’t think you’re going to get much water out of there,’” says Joe Ayotte, a hydrologist with the United States Geological Survey (USGS) in New England. “It does look pretty dry but after half a day, they pretty much fill up.”

Dug well with instrumentation. Photo courtesy of Joe Ayotte, U.S. Geological Survey

Ayotte is the inventor of a novel shallow well design, which differs from a traditional hand-dug shallow well. It is referred to as a safe, directional, drought-resistant dug well (SDDW) in the patent held by USGS. Shallow wells are often supplied from what geologists refer to as the glacial till aquifer. Glacial till is unsorted sediment resting on bedrock, remaining after periods of glaciation.

“The water in this type of well is not surface water, it’s ground water,” Ayotte says. “The water comes from a contributing area that is some distance up-gradient from the well.” According to Ayotte, the water in a shallow well is typically several years old.

To build a shallow well, you need to dig a cube, about 20 by 20 by 20 feet, and outfit it with some specific plumbing. It’s then filled halfway with crushed rock, covered with a piece of geotextile and backfilled with the material that came out of the hole (more about the construction later).This design creates an underground reservoir, which has the capacity to hold a large amount of water.

“There is an increasing need for clean and reliable supplies of water,” Ayotte says, and his design is equally suitable for domestic and small-scale agricultural uses.

“The impetus for this well design was not really about sustainability; it was about myself and many people in New England with drilled bedrock wells containing high concentrations of arsenic,” Ayotte says. Arsenic in drinking water is a growing concern in northern New England and other parts of the United States. According to the Centers for Disease Control and Prevention (CDC), long-term exposure to high levels of inorganic arsenic in drinking water is associated with certain medical conditions, including skin disorders, an increased risk for diabetes, high blood pressure and several types of cancer.

It is possible to install an arsenic treatment system but recent research suggests limited exposure reduction, despite treatment. “There is a human element, and try as we might, we sometimes don’t maintain the systems or use them properly. We turn them off, or we don’t use them because they are too slow,” Ayotte says. “Because of this, treatment systems do not fully mitigate the presence of arsenic in domestic water.”

According to Ayotte, water pumped from shallow wells is much less likely to contain arsenic than water from deep wells. This is because the shallow aquifers, covering the bedrock, produce water that tends to be slightly acidic with a pH of less than 7, and there is quite a bit of dissolved oxygen in the water. “These two features mean that arsenic is really difficult to mobilize into [the] water; the geochemistry keeps arsenic stuck to the sediments, and it doesn’t dissolve in the water,” Ayotte says.

Casing and collector being lowered into well excavation. Photo courtesy of Joe Ayotte, U.S. Geological Survey

Ayotte and his collaborators, which include New Hampshire’s Public Health Laboratory, University of New Hampshire’s geochemical laboratory, Maine Geological Survey, the National Ground Water Association and private well owners, have been monitoring and studying two shallow well test sites in New Hampshire. New Hampshire law limits the amount of arsenic in public drinking water to half the federal limit, or 5 parts per billion. Maine uses the federal limit, or 10 parts per billion. According to Ayotte, in one of the New Hampshire test wells, the arsenic levels are less than 0.5 parts per billion, which is one-tenth the New Hampshire drinking water standard. “In comparison,” he says, “a drilled well close by has an arsenic level of 6 parts per billion.”

Ayotte’s research also shows the prevalence of uranium, a radioactive heavy metal, in New England’s drilled wells; levels are more than was previously understood. “In some data, we are seeing uranium concentrations 10 times higher than the maximum contaminate level set by the EPA,” Ayotte says. Like arsenic, exposure to uranium has associated health risks and, according to Ayotte, high uranium levels are a proxy for high radon levels in parts of New England. Radon is a naturally-occurring radioactive gas that, as stated by the United States Environmental Protection Agency (EPA), may cause cancer.

Another advantage of the new drilled wells is that they have a lot of storage capacity. “New shallow wells can store five to seven thousand gallons of water in the spaces between the crushed stones. In contrast, a 600-foot [drilled] well, 6 inches in diameter, might only have 900 gallons of water,” Ayotte says. Because they only yield and store so much water, drilled wells are susceptible to drought conditions attributable to climate change. Owners of these novel shallow wells, on the other hand, may actually benefit from the changing climate; heavy rainfall events deposit more water into the glacial till aquifer.

The new shallow wells also have benefits over traditional hand-dug wells, which are typically lined with either rocks or concrete tiles and topped with a loose-fitting cap. They are susceptible to drought because they only utilize a small-diameter inflow area at the bottom of the well. Hand-dug wells are also extremely vulnerable to surface water contaminates such as fertilizer, pesticides, herbicides, manure and other hazardous materials. If there are cracks in the well’s lining or an ill-fitting cap, they can invite unwanted mammals, reptiles and bacteria.

Irrespective of the intended usage – domestic or agricultural – the construction of a shallow well remains the same. The first step is to select an appropriate site. “In terms of water quality,” Ayotte says, “do not build one close to a septic system or a place prone to something like gas spillage. In terms of water yield, the best place is where the water table is closest to the land’s surface. For example, when you have a steep slope coming down to a shallower slope, that’s a place where the water table is closest to the surface. Another possibility is to choose a lowland area where there is natural surface water like a pond or a brook.”

Once a site is selected, the construction is straightforward. The first step is for an excavator to dig a 20-by-20-by-20-foot cube. The excavator will also need to dig a trench below the frost line from the well to the building where the water will be used. Next, some crushed rock – either 1 ¼ inch or 1 ½ inch – is spread in a thin layer at the bottom of the large hole. Though Ayotte says the size of the crushed gravel isn’t critical, this size packs well and has high porosity, providing the water storage he is looking for. Once the crushed rock base is in place, a custom casing assembly is lowered into the well.

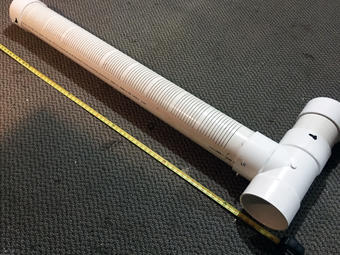

The assembly looks like an upside-down capital “T,” with the well casing forming the vertical portion of the “T”; the horizontal part of the “T” is constructed with water-grade PVC pipe customized with small slits, about two per inch, that Ayotte cuts with a skill saw.

A horizontal collector. Photo courtesy of Joe Ayotte, U.S. Geological Survey

These slitted pipes lie directly on the crushed rock at the bottom of the hole and function as collection screens for the water. Ayotte says, “The slits are large enough to let water in, but small enough to keep out stone and sediment.” The horizontal-slitted PVC section is attached to the well casing with T connectors and stainless steel hardware.

A submersible pump is then lowered into the well casing. The pump is connected to an above-ground power source, just like a drilled well. Attached to the pump is a water line that runs through the center of the casing.

Ayotte uses a rope to support the casing as the excavator backfills around it with the same sized crushed stone that was used in the base. When the hole is half full, a piece of geotextile is placed on the surface of the crushed stone around the casing. Geotextile is a permeable fabric, typically plastic, that is used to increase soil stability, provide erosion control or aid in drainage. “Geotextile fabric prevents the downward migration of sediment from the overlying fill into the reservoir,” Ayotte says.

Once the geotextile is in place, the native material that was removed from the hole is placed on top of the fabric until it reaches the frost line. At this point, a pitless adapter is installed. This is a special fitting that connects the vertical water pipe in the well through the casing wall to the lateral line running to the building.

After the pitless adapter is installed, the excavator continues backfilling until it’s up to grade. The 10 feet of material, added on top of the geotextile, acts to prevent the downward migration of contaminants. Finally, a sanitary cap is placed on the top of the well, leaving it looking very similar to a drilled well.

As for the cost in comparison to a drilled well, Ayotte says that since the technology hasn’t been commercialized, it is hard to pinpoint a precise cost. Ayotte, who installed one at his New Hampshire home 20 years ago, paid about $2,500 to dig the hole, haul the gravel and lay the water line that connects to his house. This figure also included the pump and electrical components. Ultimately, the cost will be determined by how much work the well owner is able to do and local rates, e.g., the cost of hiring an excavator operator.

Both of the New Hampshire test wells fared well during 2020’s extremely dry season. “Both wells went through the drought of 2020. They were both in continual operation the whole time and didn’t have any problems running dry or losing water,” Ayotte says.

Despite the success of these wells and the documented research that’s been published, the technology is not generally understood or accepted by government regulators, well drillers, private well owners or farmers.

“I think we’re still at the stage of infancy in getting the word out and helping people understand how these wells work and how safe they are,” Ayotte says. “Hopefully, if we can change people’s views of shallow water, this can become another tool in the toolbox to get potable water where people need it.”

About the author: Sonja Heyck-Merlin is a regular feature writer for The MOF&G. She and her family own and operate an organic dairy farm in Charleston, Maine.