|

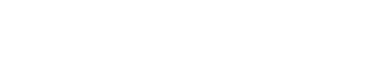

| Jessica and Ross Ludders and their sons take a break from homesteading in Exeter, Maine. |

|

| Some of the homestead plots that grow vegetables and grains |

|

| A given plot supports pigs one year, grains the next and vegetables in the third year. |

By Sonja Heyck-Merlin

Photos by Ross and Jessica Ludders

“It was like magic. I put these nasty black beans in the thresher, and a finished product came out. I was hooked,” says Ross Ludders, a graduate of the University of Maine sustainable agriculture program with an extensive background in commercial farming. In 2014 Ross and his wife, Jessica, a high school and college English teacher, moved to a 20-acre property in Exeter, Maine, and began homesteading with their sons, Baxter and Grady, now 11 and ten.

Intending to produce as much of their food as possible, they established an 80- by 80-foot organic garden their first year on the property. In some extra space they grew a crop of dry beans. Ross purchased and refurbished an antique hand-cranked blower bean cleaner and used it to clean the beans.

The success of harvesting and processing 150 pounds of dry beans “struck the excitement” for grain growing, Ross says. “The hand-cranked cleaner enabled the small-scale processing of the beans, removing the hassle and bottleneck of cleaning them by hand.”

Experimentation

A few weeks after cleaning the beans, while at the Common Ground Country Fair, Ross bought an ounce of a winter wheat called Rogosa from Eli Rogosa, an expert in heritage grains and author of the book “Restoring Heritage Grains.” Small grains are classified as spring or winter types. Winter types are planted in the fall and require vernalization to produce a head with grain. Spring types are planted as soon as the soil can be worked in the spring.

When he got home from the fair, Ross says, “I quickly planted one of our veggie beds with the Rogosa seed.” The bed was approximately 20 feet long by 4 feet wide. The following spring he planted two types of spring wheat – Red Fife and Glenn – each in a 20- by 20-foot plot. He also planted a 40- by 40-foot plot of hulless oats. For seeding, he used an Earthway precision push seeder with 8 inches between each row.

In the first year, Ross says, “I trialed two different planting rates: about 1.5 inches between seeds and 1 inch between seeds.” He found the denser planting rate allowed the wheat stands to cover open spaces with their foliage faster. The lower density left more open space for weeds.

Between his “magic” cleaner and the Earthway seeder, Ross was able to plant and clean the grain crops with relative efficiency. Threshing the grain (loosening the edible part of the grain from the rest of the plant) was the biggest challenge in the first year. “I figured I would plant a little grain, harvest it with my European scythe, hang the shocks in the barn, and then in the winter bang them with a cane on a tarp. I quickly learned that it is impossible to cut, shock and hang the amount I planted.”

Ross decided that he had to thresh the grain immediately after harvesting rather than storing it in shocks and threshing later. First he tried laying the plants on a tarp and beating them with a cane, “just like Almanzo did,” Ross says, evoking the spirit of the threshing chapter in “Farmer Boy” by Laura Ingalls Wilder. In that chapter, Almanzo’s father shuns the modern threshing machines, saying, “That machine chews up the straw till it’s not fit to feed stock, and it scatters grain around and wastes it.”

Ironically, Ross found that beating his grains with the cane, Almanzo-style, left a significant amount of wasted grain. The next approach was to mow high, hand harvesting only the heads into buckets. He then attempted to thresh the grain by using a weed whacker in the bottom of a barrel. This method wasn’t perfect either; it wasted less grain but left lots of little bits of plastic weed whacker string in the grain.

After threshing and cleaning, the family had about 50 pounds of wheat and its first taste of bread made from home-grown heritage wheat. Since that initial experiment, Ross says, “Grain has become the glue in the homestead rotation, moving it toward a more sustainable, closed system.”

The Pig, Grain, Veggie Rotation

The current system is based on a three-year rotation on about three-quarters of an acre of tilled land divided into six varying sized plots. A given plot will support pigs in year one. The Ludders family raised four pigs in 2019. The plot produces grain in year two. Although Ross has experimented with grains such as field peas and buckwheat, the current focus is on wheats and hullless oats. In year three of the rotation, the plot produces mixed vegetables (including flint corn and popcorn). With these three stages of rotation all occurring together, the family can proudly bite into a BLT as well as many other meals, produced exclusively with home-grown food.

In the early fall, vegetable plots are transitioned to next year’s pig plots by seeding the vegetable plots to winter rye with a broadcast seeder and then lightly harrowing in the seed with a 5-foot disc harrow behind a 30 horsepower Ford 1910. The following spring winter rye will provide early forage for piglets rotationally grazed using flexinet fencing. After harvesting the winter rye, Ross reseeds the plot to oats to provide additional forage for the pigs.

To transition the pigs’ plots to grain plots, Ross spreads a light load of compost made from conventional manure and spoiled silage to balance the manure hot spots that the pigs create. Then he plows with a single-bottom moldboard plow behind the Ford 1910 and harrows the compacted pig ground. He seeds winter grains at the end of September. Plots dedicated to spring grains are broadcast seeded to oats in the fall to protect the soil. The winterkilled oats will be incorporated into the soil before Ross plants the spring grains.

On plots being transitioned from grains to vegetables, Ross also plants oats as a cover crop in the fall following the compost application and tillage.

One year he applied raw manure to the grain plots but discovered that although the grain crops grew lush and green, they were more prone to lodging. “Lodging is a big deal,” he says. “Thinking about lodging makes my stomach turn. Lodged grain doesn’t dry out.”

(For information about using pig manure safely in the garden, see “Raising Organic Hogs by the Tractor Method” in the spring 2006 issue of The Maine Organic Farmer & Gardener)

Ross continues to plant both winter and spring grains at his preferred seeding rate of approximately one seed per inch and 8 inches between rows. This equals about 1.8 pounds per 1,000 square feet, which is still lower than commercial seeding rates. Some heritage grain growers advocate an 8-inch spacing between each plant in the row in order to get larger grain heads, but Ross says, “I have found that the higher density is key. I want the crop tight enough so that it shades out some weeds but open enough that I can actually weed it.”

Just before the canopy closes, Ross diligently hand weeds the grains, and anyone who has seen the Ludders homestead can attest to the dreamlike absence of weeds in both their grain and vegetable plots. “One of the biggest things,” Ross says, “is to try not to let anything go to seed. One weed that goes to seed is a million future weeds that we’ll have to pull up.”

Last year, Ross added a soft white winter wheat and a hard white spring wheat to the rotation to give him more flexibility in the kitchen. He purchased the wheat berries at a local natural food store and does not know the name of the varieties, although he would like to find named varieties locally. Soft white wheat is lower in protein (and therefore lower in gluten) and higher in carbohydrates than hard wheats, making it a better choice for muffins, cookies, pancakes, waffles, etc. Hard white wheat is a relatively new class of wheat developed by plant breeders from hard red wheats. While hard white wheat has the same nutritional claims as traditional red wheats, products made from white wheat are lighter in color and sweeter in taste.

Hulless oats, also known as naked oats, are a spring grain and an important staple in the Ludders family diet. Oats have a clinging hull that requires industrial-grade milling to prepare them for human consumption, and growing hulless oats enables processing the grain into rolled oats on the homestead. The Ludderses use a simple hand-cranked oat roller in their kitchen. Initially, Ross had problems with birds devouring the hullless oats. He says, “In the beginning of July, the oats would look beautiful. Then they would begin to lodge, and the birds would come in swarms. They would continue to land in the lodged grains, and it got worse and worse.”

Ross mentioned this problem to a commercial grain grower who recommended that he shift from the Terra variety to AC Gale. According to Ross, AC Gale has a silica sheath around it, and handling the crop is like “having fiberglass insulation around you. Switching varieties has totally solved the bird problem in the hullless oats.” Ross originally got the seed from Sean O’Donnell of Rusted Rooster Farm and now produces his own seed.

Harvest Improvements

Ross has developed a more efficient way to thresh grains since his initial attempts with the cane and weed whacker. Small-scale grain processing equipment is available but is cost-prohibitive, and Ross prides himself in solving his challenges on a shoestring budget. After watching YouTube videos about threshing grain with converted chipper shredders, Ross was inspired to purchase a used $150 McKinsey gasoline-powered chipper shredder. He modified the machine to meet his needs by removing the original transport wheels and replacing them with larger cart wheels on a homemade wooden frame. This modification both raised the machine and made it easier for him to move it around the grain plots. With the extra height provided by the frame and taller wheels, he can fit half-barrel totes beneath the machine to catch the grain and chaff. He also exchanged the metal fingers for rubber fingers to prevent grain breakage.

“I originally planned to continue hand harvesting heads only and feed them into my threshing device,” Ross says, but he found that harvesting the heads only was too time-consuming.

With a sickle, he started cutting lower on the stem and bunching, but then the McKinsey was unable to process the straw. “My current strategy is to use the chipper shredder to batter the grain out of the seed head. I hold each bundle of grain in the machine, let the rubber fingers beat the grain off, and then toss the straw into a pile.”

In 2019 Ross used his tractor and 6-foot sickle bar mower to harvest grain. He attached a 6- by 8-foot tarp to the back edge of the cutter bar, allowing it to drag on the ground and accumulate the freshly mowed grain. He then hand-bunched a tarp-load of grain and carried it to the McKinsey for threshing.

After threshing, he moves the half-barrel totes to the barn for cleaning in the hand-cranked blower cleaner. Then he uses a digital meter to determine whether the grain needs further drying. Most grains must be below 13% moisture for long-term storage. Although they seemed dry to him, Ross’ 2019 crops tested at 20% after cleaning. To dry the grains to the required moisture levels, Ross places about 50 pounds of grain on top of a screen that lies horizontally halfway down in a poly livestock water tub. Using a small electric heater and fan, he funnels warm air into a 6-inch hole at the bottom of the water tub, forcing the warm air up through the grain. After drying the grains to 13% moisture, he stores them in 50-pound bags in metal trash cans. The following table shows yields from his various plots.

2019 Grain Plots and Yield

| Variety | Square footage | Yield in pounds | Pounds per square foot |

| AC Gale hulless oats | 2,900 | 150 | 0.05 |

| Red Fife spring wheat | 517 | 13 | 0.03 |

| Unknown variety soft white winter wheat | 315 | 21.4 | 0.07 |

| Rogosa winter wheat | 1,190 | 91 | 0.08 |

| Banatka winter wheat | 1,190 | 68 | 0.06 |

| Oland spring hard red wheat | 156 | 12 | 0.08 |

| Unknown variety hard white wheat | 429 | 25 | 0.06 |

Bread and Butter

To mill flour, the family uses an electric Wonder Mill Junior Deluxe. Ross, the family breadmaker, says that he is still learning about and experimenting with the art of breadmaking, and jokes that “abandoning a wheat variety based on my baking practices isn’t the best idea.”

The family prefers a more traditional soft crumb yeasted sandwich bread over a dense and crusty sourdough-style loaf. Although they are happy with the 95% whole wheat bread that Ross makes, he plans to experiment more with a combination of hard red and hard white wheats to achieve a greater home-grown percentage. Adding the soft white has allowed them to enjoy fluffy pancakes, cornbread and muffins from their own grain supply.

Incorporating grain into the rotation has opened up opportunities that Ross did not consider when he started. Wanting to be self-sufficient in bread flour and oats has helped the homestead evolve into a more sustainable and closed system. The chaff provides bedding for their laying hens, and the straw provides mulch for their garlic and perennials. The grain also provides an expanded rotation for the pigs and vegetables. While he has found success in growing about 300 to 350 pounds of grain each year, Ross says, “Don’t just think about what it is doing for your kitchen but your whole homestead system.”

About the author: Sonja Heyck-Merlin is a regular feature writer for The MOF&G. She and her family own and operate an organic dairy farm in Charleston, Maine. Ross Ludders is Sonja’s partner’s cousin.