| COOPP: Get Your Poultry Processed Here

COOPP, the poultry processing cooperative operating in Monmouth, is open for business. It gives you a state-inspected poultry product that you can sell anywhere, including farmers’ markets, retail stores and restaurants. This is the only plant in Maine where you can get a state-inspected product to be able to sell at these venues. COOPP is processing all types ofbirds – chickens and beyond. Membership in the coop is a one-time fee of $100. Processing fees for chickens are $4.00 for members and $4.50 for nonmembers. Processing fees for turkeys range from $12.50 to $25.00, depending on the weight, for members; and $13.50 and up for nonmembers. Duck are $7.50 or $8.50. Contact Kate Dabney at 376-5166 to arrange for an appointment. |

by Diane Schivera

Housing for livestock becomes more important as winter approaches, and if you don’t have housing for animals that you acquired this summer, plan that housing now and start building as soon as possible.

Many animals will live nicely with little to no housing: A stand of conifers can suffice for beef cattle, some dairy animals and sheep, but they will require more feed for energy to keep warm in the cold, and their level of production or gain will be reduced.

Watering and fencing could be more difficult. Animals require a good supply of water to keep hydrated. Cold air has less moisture than warm air and will suck water out of an animal, especially in a breeze or wind. Hauling buckets in the snow is difficult, and you need a system that can drain. You can hang a hose that comes from a hydrant that won’t freeze or that comes from an inside line. Also, frost-free set-ups exist that go to nose pumps (the animal pumps the water with its nose). These back drain and won’t freeze.

Electric fencing is not as effective in the snow unless you run a ground wire along with the hot wires in your fence. This “earth wire return system” (alternating electrified and ground wires) is available in the Premier catalog (www.premier1supplies.com) or from fence dealers.

Important Considerations for Housing

Windows

Place windows high enough so that animals can’t break them but they provide enough light for you to see to do chores. The animals need enough light to “feel alive.”

Have enough south-facing windows to provide heat in the winter.

Ventilation is critical. Animals that are forced to breath air with ammonia from urine have stressed respiratory systems, and stress results in disease. Drafts of cold air can be just as damaging, though. Ensure good airflow without drafts by having large enough openings in the direction of prevailing winds. High windows that open in from the bottom work well.

Cleaning

If possible, arrange stalls or pens so that, in small operations, you can easily scrape manure and bedding into a wheelbarrow. Larger operations benefit from a central alley where manure and bedding can be collected with a tractor bucket.

My dream chicken house would be far enough off the ground that I could use a shovel to scrape manure and bedding from the floor into a wheelbarrow sitting under the door opening. The area under the coop would also give birds a shady place.

A chicken house with a removable droppings board under the roost, or a board that can be easily scraped into a bucket, makes frequent cleaning a breeze.

Drainage

Install gutters that move water away from the building.

On wet sites, put gravel or tiles around the foundation or footings.

Flooring

Soil, sand or gravel is easier on animals’ legs than concrete and works well with a deep bedding system or bedded pack system – i.e., starting winter with a good 6 inches of mulch hay (but not moldy hay), straw or shavings and adding more bedding as the initial bedding becomes soiled over the season. Using this system, housing needs to be cleaned only yearly. The system works well if you can aerate the bedding with a pitch fork (in small areas) or a tiller or tractor with a tine (in bigger areas).

A wood floor can be scraped clean but becomes slippery, and rodents live happily under wooden floors – especially if you’re feeding grain. Rubber mats, available in various sizes, make a non-porous surface that is easy to clean.

Concrete is the easiest floor to clean but is hard on animals’ feet and legs and is more expensive to install. Rubber mats can make concrete more comfortable for animals and can reduce the amount of bedding they need to lie on.

Construction and Layout

Lee Pelley’s book In One Barn (Countryman Press, 1984) has extensive information about barns for rabbits, pigs, sheep, cows and horses, housed separately and in combination. Pelley thinks that poultry should not be housed with milking animals, because they can expose the mammals to avian TB, which will cause the milking animals to test positive to TB and require that they be euthanized.

A pole building is the least expensive option. The other extreme for beauty and expense is a post and beam barn. You can build a simple three-sided shed with pole construction for animals that need minimal protection only in the worst weather. Pole construction is strong and simple and allows for a second story for hay storage. The poles eliminate the need for a concrete foundation, but protect the poles from rotting somehow if you plan to have a bedded pack. Cedar or locust makes good, rot-resistant poles. Remember that if you use chemically-treated wood, animals must not come in contact with it, or they cannot be part of a certified organic farm.

Cooperative Extension has large books filled with plans, layout and construction methods for larger barns, and one book with ideas and dimensions for smaller structures, such as a two-cow building.

Remember to plan for hay storage space. A Jersey sized milk cow, for instance, needs about one bale of hay a day when it’s not on pasture.

Poultry Housing

A house for laying hens does not need insulation, even in Maine, but, as mentioned, animals kept in colder situations will need more feed and will produce less. Maintain a 14-hour day with lights to maximize egg production.

Many plans are available on the Internet (Google “poultry housing”) and in books. Stromberg’s Hatchery catalog (www.strombergschickens.com) lists several books. Poultry Houses & Appliances, A DIY [Do It Yourself] Guide, is fun and has plans for a brooder house, layer houses and a grain distributor. All the plans describe the construction methods completely and clearly. This book also tells about basic construction techniques, including mixtures for wood preservation; and it includes plans for two rollaway nest boxes that protect eggs from being pecked.

|

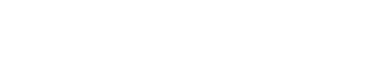

| Curtain House |

The Maine Agricultural Experiment Station Twentieth Annual Report 1904 (available in the MOFGA library) includes Bulletin 100, “Poultry Management at the Station,” which explains management methods, including feed rations. Poultry production is described as giving “greater returns for smaller capital investment,” but the “disadvantages lie in the demand for greater skill, patience and courage than will suffice for any other special, or general farm industry.”

The Curtain Front House for 50 laying hens, also described in Bulletin 100, is often seen in the back fields of old farms that used to or may still raise chickens. This stationary structure is made in 20- by 14-foot sections, with the back wall 5.5 feet high and the front 6 feet 8 inches high. The front wall has two 12-light windows on either end. The middle 3- x 8-foot area between the windows is separated into three framed sections, and a panel of framed 10-ounce duck fabric, 10 feet x 30 inches, covers the opening. (The 3-foot dimension has 3 inches of wood frame on either side, hence the 30-inch-wide fabric.) The middle panel is hinged at the top and can be raised with pulleys to hang from the ceiling inside the house during good weather and closed during bad weather.

|

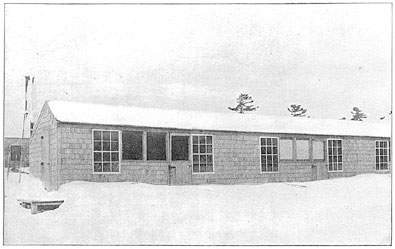

| Curtain House interior |

Three roosts along the back wall are above a droppings board. Another, identical panel of linseed oiled duck is lowered in front of the roost (14 inches out from the third roost, farthest from the wall) on cold nights. The back wall of the house is insulated with shavings or packed hay, and an inside wall contains the insulation. This construction method eliminates frosting of walls in winter. An access door on one end lets people in and out, and chickens use a small door on the front. Nest boxes are on the end.

The Curtain Front House has “trap nests” that trap the chickens so that you can see which birds are producing eggs. With two sections to the box and a landing board in front, both reduce the likelihood that chickens will walk in and break eggs.

Other Curtain Front House designs are in the USDA Farmers’ Bulletins Nos. 351-375 at (Farmers’ Bulletin No. 355 – A Successful Poultry and Dairy Farm)

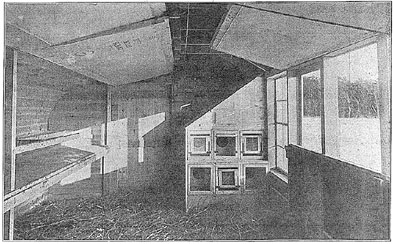

John Belding of Little Falls Farm in Harrison describes his poultry tractor:

“I came up with the big wheel idea from having a set of nice wheels and no place to put them! Also, the need to move a heavy pen with as little effort as possible. The wheels are centered on opposite sides of the pen. My tractors are 12 feet square.

|

| Belding Chicken Tractor |

“Each wheel is attached to a 1- x 6-inch piece of hardwood, a lever – in my case oak – 9 feet long. (The hardwood needs to be a full inch in thickness; thicker is fine.) The wheel is attached to the hardwood by a 4- x 6-inch metal plate, onto which I welded a 6-inch-long axle, which supports the wheel. The plate is bolted to the hardwood lever, with four 1/4-inch carriage bolts, about 1 foot from the pivot point, which is a 5/8-inch bolt, 3 inches long, through both the lever and an upright piece of hardwood attached to the top and bottom of the tractor frame. I used 5/8-inch flat washers between the wood and on each end of the bolt. The bolt has two nuts, one a lock nut.

“There is no perfect formula for the exact positioning of the pivot point and the wheel. It depends upon the construction of the tractor frame and whether a metal roof makes one side of the tractor heavier – as in my case, so I moved the pivot point slightly closer to the roofing side, which in turn moved the wheel off center toward that side also. With the wheel on the ground, the lever is not horizontal, but inclined to about 1.5 to 2 feet at the end, which should stick out at least 1 foot beyond the corner of the tractor. The pivot point, at the opposite end of the 1 x 6, is below the center of the wheel.

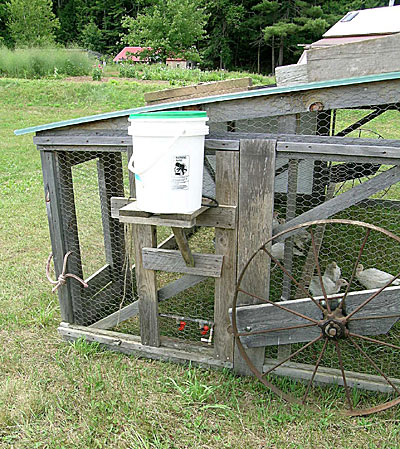

|

| Belding Chicken Tractor detail. |

“To determine the pivot point, set the wheel on the ground, lift the long end of the lever about 1 to 2 feet above horizontal, and then mark the position of the pivot point before drilling the hole in the upright. Once the pivot bolt is in place, the lever is pushed down, moving the wheel down, lifting the tractor frame, and then the lever is held in place under an L-shaped concrete anchor bolt, the L pointing down, through the tractor corner posts. My corners are 3- x 3-inch hemlock. I attached a short loop of heavy rope to the corner post, to pull the tractor with, once the lever is engaged.

“Smaller wheels can be used, but do not work as well on rough ground. My large wheels are about 30 inches in diameter, and I have one tractor with 12-inch wheels.”

– – – –

When you plan the layout for your barn, remember to give your livestock a healthy, clean, well ventilated and lit space that is also convenient and efficient for you. The easier it is to care for your livestock, the more time you will have to enjoy them.

Diane Schivera is MOFGA’s organic livestock specialist. You can contact her at 568-4142 or [email protected].